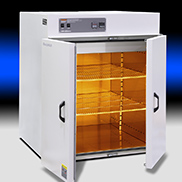

Benchtop and Lab Ovens

High-performing and solidly built using corrosion-resistant materials and over a century of manufacturing experience, Despatch laboratory ovens are the epitome of technological advancement and superior quality. Our industrial ovens deliver invariable, uniform temperature for as long as the oven is in service thanks to its solid build quality and design.

Despatch industrial oven designs have been perfected version after version to deliver higher performance on a smaller footprint with low energy consumption. Standard benchtop laboratory ovens are versatile enough to handle a range of applications, and operate with unprecedented heating accuracy, temperature uniformity, and process repeatability.

The Despatch LBB Forced Convection Benchtop Oven features a combination of horizontal and vertical airflow that offers excellent temperature uniformity at a moderate price. It is recommended for a variety of laboratory and production applications including drying, curing, annealing and materials testing. Powerful open coil heating elements and a forward curved fan deliver faster heat-up rates and short processing times. Digital controls regulate temperatures within tight tolerances. A 3/4 inch (1.9cm) LED panel displays temperatures in large, bright, easy-to-read numbers. Temperatures can be reported in either Fahrenheit or Celsius. The LBB is designed and manufactured to provide years of dependable service. The fan and heater are top-mounted to prevent damage from spills.

The LAC Benchtop Oven features horizontal recirculating airflow and exceptional temperature uniformity. The result is proven reliability in demanding production and laboratory applications, such as curing, drying, sterilizing, aging, and other process-critical procedures. The high-performance benchtop oven delivers temperatures up to 260℃ (500℉). The LAC uses horizontal recirculating airflow to ensure uniform temperatures throughout the oven. A high-volume fan circulates air through perforated, stainless steel walls to create a constant horizontal airflow across all sections of the oven. Standard digital controls regulate temperatures within tight tolerances and provide high limit protection. For more advanced control choose the optional Protocol 3™ microprocessor-based temperature and hi-limit controller with large LCD display and real time clock for auto start capability. Data-logging functionality enables reporting and analyzing and data files can be exported via the controller’s USB port. Modbus RS485 communications are included for easy data access.

The RAD1-42 Benchtop Oven features horizontal recirculating airflow and exceptional temperature uniformity. The result is proven reliability in demanding production and laboratory applications, such as curing, drying, aging, UL testing and other process-critical applications. This high-performance oven delivers temperatures up to 343℃ (650℉) and has a 4.2 cu ft (117 liter) capacity perfect for small parts, small lot sizes or tight space considerations.

The Qmax High Performance Benchtop Oven is specifically designed to meet the frequent air changes and tight temperature uniformity required of the ASTM 5423 Type I & Type II oven specification. A high-volume fan circulates air through perforated, stainless steel walls to create a constant horizontal airflow across all sections of the oven. The result is highly uniform airflow to easily meet ASTM 5423 Type I and II specification while tested according to ASTM 5374.

The Qmax oven exceeds the ASTM 5423 Type II performance requirement with a temperature variation of less than 6°C at 300°C while maintaining 100-200 air changes per hour. In addition, the brass bar thermal lag time showed superior oven temperature recovery. These ovens can be used for applications such as thermal evaluation of electrical insulating materials, testing, aging, curing, drying, sterilizing and other thermal applications where tight temperature uniformity is required.

Despatch’s RBC Burn-In Benchtop Ovens offer maximum flexibility for small lot qualification testing, burn-in, reliability testing, and research and development. The stackable burn-in benchtop ovens allow users to run concurrent tests utilizing different temperatures or different cycle times. They are ideal for qualification testing with small lots, because a new test may be started on the second chamber while the first test is still in progress. This oven configuration is designed to maximize throughput and equipment utilization. The oven may be placed on a benchtop, or stacked to conserve valuable floor space. The small footprint makes these ovens ideal for test labs or production areas where space is at a premium. Standard digital controls regulate temperatures within tight tolerances and provide high limit protection. For more advanced control choose the optional Protocol 3™ microprocessor-based temperature and hi-limit controller with large LCD display and real time clock for auto start capability. Data-logging functionality enables reporting and analyzing and data files can be exported via the controller’s USB port. Modbus communication (RS485) is standard or you can select the optional ethernet connection. The Despatch Protocol Manager network utility software enables the operation of up to 32 Protocol 3™ and/or Protocol Plus controllers from a single, remote PC using RS485 communication.

Manufacturer for Benchtop and Lab Ovens: Despatch Industries

Your Contact